A Note on Automobile

Cruise Control Faults and Sudden Acceleration [ or

Unintended Acceleration]

by Dr Antony

Anderson C.Eng FIEE

7.

Cruise Control Systems : Possible Intermittent Failure

Mechanisms

Surface leakage affecting high impedance circuits

- two research investigations - (1)

single-point-faults causing operational amplifier

malfunction - (2) intermittent open and

short circuit effects reproduced - Water

ingress - Effects of EMI - Summary

In the discussion of sudden acceleration incidents, the

focus seems mainly to have been on the external

sensors, wiring and interlock arrangements and on the

likelihood/unlikelihood that faults in these could have

serious consequences. Surprisingly little

attention seems to have been paid to the possibility of

an internal cruise control module fault causing a

throttle actuator malfunction.

Two lines of argument discounting potential

faults within the cruise control module seem to be

deployed :

- If a cruise control fault were intermittent,

it would leave traces that would be readily identified

afterwards. Therefore, if no traces are found, then no

intermittent fault can have occurred.

Comment: Iintermittent electrical faults, as a rule, are

notoriously difficult to detect. Sometimes an

intermittent short or open circuit may leave visible

signs of overheating or micro-arcing on a printed

circuit board or a connector, but at other times damage

may be on such a microscopic scale that it is likely to

go undetected. Therefore inability to find anything

wrong by inspection after the event or by trying to

reproduce the incident either by workshop tests or road

testing is no guarantee of the absence of an

intermittent fault . Note 1.

- If a cruise control module or its external system

wiring should develop an intermittent fault the

consequences are likely to be benign. Therefore, if

non-benign events should occur, they are unlikely to

have been caused by an intermittent fault.

Comment: Some intermittent faults may be benign, but not

necessarily all. If a rogue signal gets through to the

power stage of the throttle actuator while this is

electrically de-energised the fault will be benign. If a

rogue signal gets through to the power stage when this

is electrically energised then it may drive the throttle

to the closed position (benign) or to the open, in which

case the engine will accelerate or, perhaps refuse to

decelerate when the driver brakes.

Much of the discussion in the courts seems to have eddied

around:

- the driver and his/ her alleged propensity to press

the accelerator rather than the brake;

- the ergonomics of the design of accelerator and

brake pedal positions;

- the likelihood/unlikelihood of the driver being

able to stop the car by applying the brakes, if the

throttle should fully open;

- the adequacy or otherwise of the measures taken by

the manufacturers to provide interlocks to prevent the

cruise control being operated inadvertently;

- the validity, or otherwise, of simulations of

possible modes of failure in the associated wiring and

connections for sensors, actuators and switches;

- speculation on the likelihood/ unlikelihood that

two or more failure modes could arise simultaneously;

- possible sources of RFI external to the

vehicle and whether or not these might adversely

affect the electronics.

Note

2

The patent record suggests surface

leakage currents may cause high impedance circuits to

malfunction.

Patents relating to cruise control systems go back over

30 years. (US

Patent 3,455,411 of July 15 1969.) A feature of a

number of early cruise control designs is that the speed

reference voltage is stored on a low-leakage capacitor

forming part of a high impedance sample and hold

amplifier. Such high impedance circuits are very

sensitive to surface leakage currents and noise. Click

for typical arrangement of sample and hold speed

reference circuit

US

patent 3,937,980 February 10, 1976

suggests that the development of electronic cruise

control systems has not been trouble free, especially in

connection with the design of high impedance sample and

hold amplifiers. The problem relates to minimising the

effects of surface leakage on printed circuit boards.

If, for some reason, an unintended leakage path appears

to a source of voltage that is higher than the capacitor

voltage, it will charge up to the higher voltage. If, on

the other hand, the leakage path is to a source of

voltage that is lower than the capacitor, it will

discharge to the lower voltage In either case, the

result of leakage will be that the speed reference

voltage will drift away from its intended value, with

potentially serious results as far as the control of

vehicle speed is concerned.

This particular patent relates to potential guard

rings designed to overcome leakage problems found in

earlier cruise control modules. It describes very

clearly some of the problems that electronics engineers

have come across when using printed circuit boards in

harsh environments, such as the engine compartment of

automobiles. For example, the abstract says :

" When a conventional printed wiring board

is subjected to a harsh environment, leakage can

develop between adjacent conductors over a period of

time. If high impedance circuits are employed on the

board, such leakage can adversely affect circuit

performance. The effect of such leakage can be

minimised if the circuit layout is so arranged that

potentially troublesome leakage occurs only to

elements that operate at comparable operating

potentials. In one embodiment of the invention a

circuit is shown having a high impedance point on a

printed wiring board intended for an automotive

application. The high impedance wiring conductor is

completely surrounded by a metal conductor that is

connected to a potential point in the circuit that

approximates the potential at which the high impedance

point will operate. When the automotive environment

results in surface leakage, there will be very little

change in the operational character of the high

impedance circuit."

Broadly speaking the picture the patent presents of a

harsh environment is comparable to that presented by

Kimseng below. The patent continues :

"The combination of moisture with corrosive

fumes constitutes a particularly severe problem

because it can create conductive paths on insulating

surfaces. This means that conductive paths exist where

none are desired. This is most troublesome in high

impedance circuits. Ordinarily solid state circuits

operate at low impedance levels and are relatively

tolerant of moderate leakage. However in some

applications high impedance circuits are called for

and these constitute a particular problem."

The particular components that the patent highlights as

being vulnerable to leakage are the high quality

capacitors [Note 3] used to store speed reference

voltages, in which very little leakage can be tolerated

because the reference voltage must be kept constant for

extended periods of time. To overcome the leakage problem

the high impedance points of a printed circuit board are

individually surrounded with a closed ring of conductive

material.

"This ring can be a separate conductor or

in the interest of economy it can be part of the

regular wiring. The ring is connected to a source of

d-c potential that approximates the operating

potential of the high impedance point. Thus even

though some surface leakage develops the leakage will

not alter the potential at the protected point to the

degree that uncontrolled leakage would produce."

The patent then continues:

"In a typical embodiment of the invention

in an automatic speed control circuit, a high

impedance point is surrounded with a conductor ring

that is connected to the reference source potential

which represents the d-c voltage level that the high

impedance point will normally achieve. This action in

practice constitutes a safety feature. If the high

impedance point were to develop uncontrolled leakage

to a point of substantially different potential, the

speed control circuit could malfunction to result in

excessive accelerations of the vehicle."

This paragraph implies : (a) that if surface leakage

develops on a cruise control module printed circuit

board it may result in charging or discharging the memory

capacitor causing the speed control circuit to malfunction

and possibly cause excessive accelerations of the vehicle;

(b) that that the guard ring constitutes a safety feature

that protects against excessive accelerations. By

implication, if the guardring should become disconnected,

wrongly connected or omitted, it will cease to fulfil its

safety function. Without an effective guard ring, moisture

and corrosive fumes may cause leakage currents on

insulating surfaces which in turn may cause the memory

capacitor to overcharge or to discharge, thereby causing a

risk of an excessive acceleration.

The originators of the patent have focussed on an

innovative way of reducing the effect of leakage

in a high impedance circuit in a hostile environment.

They do not appear to have considered the alternative of

using a low impedance drift-free speed reference

circuit, such as might be the practice with a P +I

controller used in an industrial application.

The message from this patent is that high impedance

electronic circuits in cruise control systems may suffer

from leakage problems because they operate in a hostile

environment, where it is very difficult to maintain the

integrity of insulation over long periods of time.

Two research investigations into

cruise control system failure mechanisms

Two independently executed research

investigations, neither of which appear to have been

brought to the attention of the courts, have

examined cruise control modules and have sought to

establish what failure modes in might arise in these and

whether any of these modes might cause sudden

unexplained acceleration. They suggest some possible

fault mechanisms that may have occurred in particular

types of cruise control systems:

- Gunnerhed, M., Risk

Assessment of Cruise Control FOA Report E 30010

-3.3 May 1988 ISSN 0281-9937 Swedish Defence

Research Establishment, Department of Information

Technology

Gunnerhead focusses on the possible impact of

intermittent faults resulting from a broken track or

cracked joint on the PCB of a proprietary analog cruise

control module using operational amplifiers and with an

electropneumatic throttle actuator. He records that it

appeared from the circuit diagram that there were no

single-point-fault modes that could trigger a sudden

acceleration. However, when the printed circuit board

was examined, it became clear that a break in a specific

connection would cause a single-point-fault mode

by causing changes of state in two supposedly

independent operational amplifiers : the pump motor

would start and simultaneously the regulator valve would

close, resulting in the throttle immediately opening

fully and causing a sudden acceleration. Clearly such

single-point-fault modes involving operational

amplifiers are very particular to the individual design,

but this report demonstrates that they can sometimes

arise. See note 4 on high gain operational

amplifiers

- Kimseng, K. , Hoit,

M., Pecht, N., . Physics

of Failure of a Cruise Control Module

Microelectronics Reliability Vol 39, pp. 1423-1444

February 1999.

Kimseng et al report that

over a five year period owners of a particular type of

cruise control unit have complained of a variety of

faults : from not engaging on command, to the cruise

unexpectedly accelerating past the desired speed. They

observe that a common thread to the complaints was the

intermittent nature of the problems. More than 96% of

the reported failed modules removed from vehicles and

returned to the unnamed automobile company passed bench

tests. They report that up till the end of Oct 1997

the company in question had spent more than

$600,000 on parts alone for cruise control warranty

replacements for its 1996 vehicles and that the 1997

fleet was showing the same pattern. Note 5

Kimseng et al tested 9 cruise control modules in

all : five which had been returned two years previously

under warranty with intermittent faults that checked out

OK on bench tests and four new units straight from the

manufacturer. Their investigation did not address

vibration, but focussed on laboratory simulation of heat

and humidity conditions in the engine compartment. In

accelerated tests they demonstrated that

intermittent open and short circuits developed in a

manner that appeared to be consistent with the

service reports of intermittent faults. Both

returned and new units demonstrated two similar failure

mechanisms : (1) high resistance fretting between

separable interconnects and (2) PCB shorting from

humidity and contaminants. Both failure mechanisms

vanished after a while once the cruise control module

was removed from the test oven and had been allowed

to 'sit' for an extended period. The authors

expressed the opinion that : "It is possible that some

combination of these failure mechanisms is causing the

CCM failures and could explain the runaway acceleration

especially if the power line shorts with the motor

line."

The results of these two investigations suggest the

possibility of several inherent modes of failure within

cruise control modules that can be initiated by the

occurrence of open and short circuits on the PCB or at the

board connectors. The findings of both reports

appear to match anecdotal field reports that cruise

control fault events appear to be random and intermittent

and are not easily identifiable afterwards and sometimes

occur when the cruise control is not engaged.

From a control system point of view, intermittent

open or short circuits on the control module PCB suggest

the following possibilities:

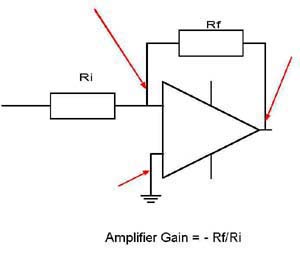

- open-circuited feedback resistors in a high gain

amplifier that may saturate the amplifier;

- open circuits leading to disconnection of clamping

or biassing circuits resulting in the change of state

of one or more logic gates or amplifying elements;

- leakage currents that charge up the integrating

capacitor of a P & I controller and may

drive it into saturation;

- pull down resistors on logic inputs which

fail to do their job and which make logic inputs

sensitive to stray RF inputs;

- leakage of charge to or from voltage reference

capacitors that may cause errors in the speed

reference voltage(s) of the cruise control module.

If a single intermittent fault occurs on a printed circuit

board, then there is a possibility that this will cause a

false, or rogue control signal that will instruct the

throttle to open. In other words, a single fault in the

PCB in the wrong place may cause sudden acceleration.

There is therefore no need to postulate, as the NHTSA do,

a requirement for concurrent multiple intermittent faults

before a sudden acceleration incident could occur. A

single fault at a critical point within the cruise control

module might well be sufficient. Arguments

that suggest that two or more simultaneous faults

are "virtually impossible" lose most of their force when

it is realised that a single internal fault in a critical

place may be all that is necessary.

The picture is now becoming clearer. (1) Some of the

electronic circuits used in automobile cruise control

are high impedance, sensitive circuits that can

potentially suffer from leakage because of the

harsh environment in which they work. (2) the electronic

circuits are vulnerable not only to leakage but to

intermittent faults (open and short circuits) developing

as a result of either the ingress of moisture and

pollution or vibration, separately or in combination (3)

cracks in PCB tracks may cause the characteristics of

certain functional elements of the circuit to change

intermittently from one state to another (4) the results

of (1), (2), or (3) may change the characteristics of

the cruise control module sufficiently to qualify as an

intermittent fault condition.

Measures can be taken to minimise the likelihood of

internal intermittent faults, but they cannot be

eliminated altogether. When intermittent internal faults

occur, there is a possibility that they may cause

the throttle actuator to operate, without there

necessarily being a fault in the external control and

interlock logic. There is no guarantee that the

fault diagnosis systems currently in use will detect

internal intermittent faults.

Since the RoHS Directive was adopted by the EU in

February 2003, lead free solders have now become the

norm. However, lead free solders are sensitive to tin

whisker formation. These very fine whiskers, much finer

than the finest human hair, can form intermittent fault

paths between printed ciruit tracks that can momentarily

carry high currents. They rarely leave a significant

trace behind them afterwards. For further reading on

this subject see the NASA website at http://nepp.nasa.gov/whisker/background/index.htm

Water ingress

There can be little doubt that moisture ingress has

been the cause of some sudden accelerations, the

incidents in a Proton Waja in Malaysia mentioned earlier

being but one example. Sudden accelerations in car

washes seems to have affected Cherokee and Grand

Cherokee Jeeps in particular. The International

Car Wash Association has alerted its members to the

danger of vehicles suddenly accelerating during or after

the car washing process on a number of occasions. As

long ago as September 1988 the ICA advised vehicle

handlers: "Car wash employees should be constantly

reminded to turn off the ignition key when handling a

runaway automobile, when the natural tendency is to put

both feet on the brakes and push as hard as

possible. Simply reaching down and turning off the

ignition will minimize the damage in collisions and

runaways." In 2003 the ICA issued a reminder reminder

to members to report sudden acceleration

incidents so that they could continue to monitor the

situation and be prepared for future actions. In 2006

the ICA issued a revised advisory

notice in an attempt to minimise the risk

of sudden accelerations with Cherokee and Grand Cherokee

Jeeps. On June 13th 2006 Connecticut's Attorney General

Richard Blumenthal and State Representative Patricia

Widlitz called upon NHTSA to investigate sudden

acceleration problems in late model Jeep Grand

Cherokees, saying that NHTSA should require Daimler-Chrysler to

provide all information concerning sudden or

unexpected accelerations, and request information from

car wash owners, auto repairers and insurance

companies.

"The rate and

severity of these sudden acceleration incidents

suggest a severe structural flaw - certainly more than

simple coincidence," Blumenthal said. "These incidents

- in one case killing a Connecticut man - call for

aggressive and vigorous action to prevent another

needless, preventable tragedy. No safety official can

be neutral: a full-gear federal investigation is

vital."

Widlitz said, "It

is imperative that the National Highway Transportation

Safety Administration immediately launch an

investigation into the Jeep Grand Cherokee sudden

acceleration incidents. How many deaths and injuries

must the public endure before this issue gets serious

attention?"

Two days later On June15 2006 , a

52-year-old employee, who had worked at Thunderbird

Car Wash for the past 12 years, got into a 2006 Jeep —

with less than 4,000 miles on it — to drive it off the

conveyor. When he put the car in "drive," it

accelerated out of the tunnel, smashed the open door

of a Cadillac, squeezed between two other cars, jumped

a curb and was about 75 feet down a street before he

brought it under control. Report

in Carwash News For further

reading, Doug Newman a New England car wash owner has

had several sudden acceleration incidents in car washes

that he owns and has gathered a considerable body of

information together on his website at http://jeepsua.googlepages.com/home

Sayler, Bizzak and Nocivelli in their Formal

Petition

to

the

National

Highway

Traffic

Safety

Administration

Re.

1991-1995 Jeep Cherokee and Grand Cherokees

(2002) identified the 60 pin connector to the

Power Control Module (PCM), as a point where water

ingress could potentially cause the cruise control to

malfunction. Although this work relates to a specific

PCM and cruise control configuration, nevertheless it

demonstrates that multipin connectors have the potential

for developing sneak circuits that may cause

malfunctions. Multiple parallel faults become a distinct

possibility at the connector interface. This study puts

the incidence of sudden accelerations in Jeep Cherokee

and Grand Cherokees in the context of lesser rates with

other vehicles - they make the case that this shows that

sudden accelerations are vehicle-related rather than

driver related.

Possible Effects of

Electromagnetic Interference (EMI)

The effects of electromagnetic interference (EMI)

on sensitive electronic circuitry should always be

considered as a possible contributory factor to

malfunction. For example, the 1995 NASA Report

on

Electronic

Systems Failures and Anomalies Attributed to

Electromagnetic Interference refers to the

following:

- 8 NASA pre-flight case histories;

- 7 NASA in-flight case histories;

- 17 case histories involving aircraft, ships

and automobiles;

- 29 incidents where electronic devices carried onto

aircraft by passengers have interfered with aircraft

equipment;

- 4 case histories involving medical equipment,

such as an ambulance radio interfering with a heart

monitor/defibrillator and police, fire, or CB

transmitters causing runaway electric

wheelchairs.

The NASA Report says that when Mercedes Benz first

equipped their automobiles with Automatic Braking Systems

(ABS) these vehicles had severe braking problems along a

certain stretch of the German autobahn. The brakes were

affected by a nearby radio transmitter when vehicles

applied them on a curved section of the autobahn. A

short-term solution used was to erect a metal mesh screen

alongside the roadway to attenuate the Electromagnetic

Interference and enable the brakes to function

properly.

There is anecdotal evidence to suggest that, for

example, on-board mobile amateur radio equipment, if not

properly installed, may upset automobile cruise

control circuits. However, generally speaking, for

external RFI, the vehicle engine compartment will act as

a Faraday cage and should provide a fairly high degree

of screening.

When it comes to consider EMI generated within the

automobile engine compartment the situation is very

different. The most potent sources are probably

:

Whether EMI will have any effect on the electronics

will depend (1) on how effective the screening measures

are in the first place (2) whether those measures remain

effective over the working life of the vehicle. In the

presence of RFI, which will be particularly strong in the

case of spark ignition engines, a poor earth, a broken

screen, a high resistance connector etc., may be all that

is needed to allow the electronics to be subjected to an

unacceptably high level of transient disturbance, with the

potential for causing malfunctions in logic and motor

driver circuits. [A factor that needs to be taken into

consideration in most vehicles is the use of common

ground earth returns through the vehicle body, rather than

separate returns directly to the battery negative

terminal. Transient high currents generated by one

component may cause a local ground lift

at its grounding point which may affect other components

if grounded at the same point. This is particularly the

case where, after some years, the contact resistance at

the grounding point in question has risen due to the

effects of corrosion.]

Many throttle actuators now use small stepper

motor drives, which are driven by means a series of

control pulses originating in the cruise control module

or the engine control module (PCM). In the event of

stray RF derived pulses appearing at the input of the

stepper motor driver circuit, particularly if a logic

hold-down resistor should go open-circuit, these may

cause a false movement that will either open or close

the throttle. Note 6

Increasingly, automobile electronics are adopting

CAN-Bus or similar multiplexing technology to enable

communication between sensors, electronic control units

and actuators. [Note 7] Whilst Bus systems have

significant advantages in terms of reduced wiring

harness weight and complexity, they may also introduce

new potential system failure modes - for example,

the "babbling idiot syndrome" where, for some

reason, the system momentarily overloads and can

no longer handle the message transfer

requirements. What is evident is that once data is

transmitted over a common network, rather than point to

point, the system design becomes critical.

It becomes necessary to consider the potential

interactions of sub-systems that, although not coupled

from a functional point of view, and although hopefully

protected from undesirable EMI interaction, may be

disrupted by communications bus overloads and other

kinds of bus malfunction should these arise.

With regard to sudden acceleration problems that may

arise with electronic throttle controls, a

presentation by Professor Todd Hubing to the National

Academy of Sciences Sudden Acceleration

Investigation Committee in July 2010 is of particular

interest and relevance. See Hubing: 'Analyzing

Unintended Acceleration and Electronic Controls' http://onlinepubs.trb.org/onlinepubs/ua/100701hubing.pdf

.

Summarising

- Cruise control Patent literature suggests that it

has been known since 1976 that surface leakage in high

impedance circuits, particularly in sample and hold

circuits, may cause single-point-fault modes

that can result in excessive vehicle accelerations.

- The work of Gunnerhead (1988) has shown that for

one particular kind of analog cruise control with an

electro-pneumatic actuator a single cracked track in a

PCB could cause a single-point-fault mode resulting in

two supposedly independent operational amplifiers

changing state, such as to cause the throttle to open

fully.

- The work of Kinseng et al (1999) has demonstrated

that intermittent open and short circuit faults on

cruise control system printed circuit boards can be

reproduced in accelerated laboratory tests and that if

the boards are allowed to sit for a while the faults

disappear. Their view is that : "It is possible that

some combination of these failure mechanisms is

causing the CCM failures and could explain the runaway

acceleration especially if the power line shorts with

the motor line."

These three sources consistently point to the possibility

of single-point-fault modes occurring within the cruise

control module that have the potential to cause the

throttle to move to the fully open position.

Particular implementations of cruise control might be

more, or less susceptible to the same kinds of problem.

The incidence of failure will be largely dependent on

how well the particular manufacturer anticipates the

whole gamut of possible failure modes, internal and

external, and incorporates measures to prevent their

occurrence in his designs.

None of these three sources specifically mention the

possible effects of RFI. However, in my view, depending

on the particular type of cruise control unit used, RFI

from the ignition and/or starter motor, or mechanically

induced RFI caused by intermittent speed

sensor connections, might well be factors in causing

system malfunction.

One manufacturer places the cruise control module behind

an additional bulkhead within the engine compartment,

which rather suggests he is taking a "better safe than

sorry" approach by raising the level of protection against

both RFI and pollutants.

In my opinion, Hubing's work on analysing unintended

acceleration and electronic controls (July 2010) mentioned

above represents a significant advance in the state of the

art regarding the understanding the phenomenon. I would

suggest that anyone wanting to improve their own

understanding of the underlying issues should read his presentation

to the NAS carefully. |